Shop by Category

Fittings

5 products

Showing 1 - 5 of 5 products

Essential Gas Strut Fittings: End Connectors & Mounting Hardware

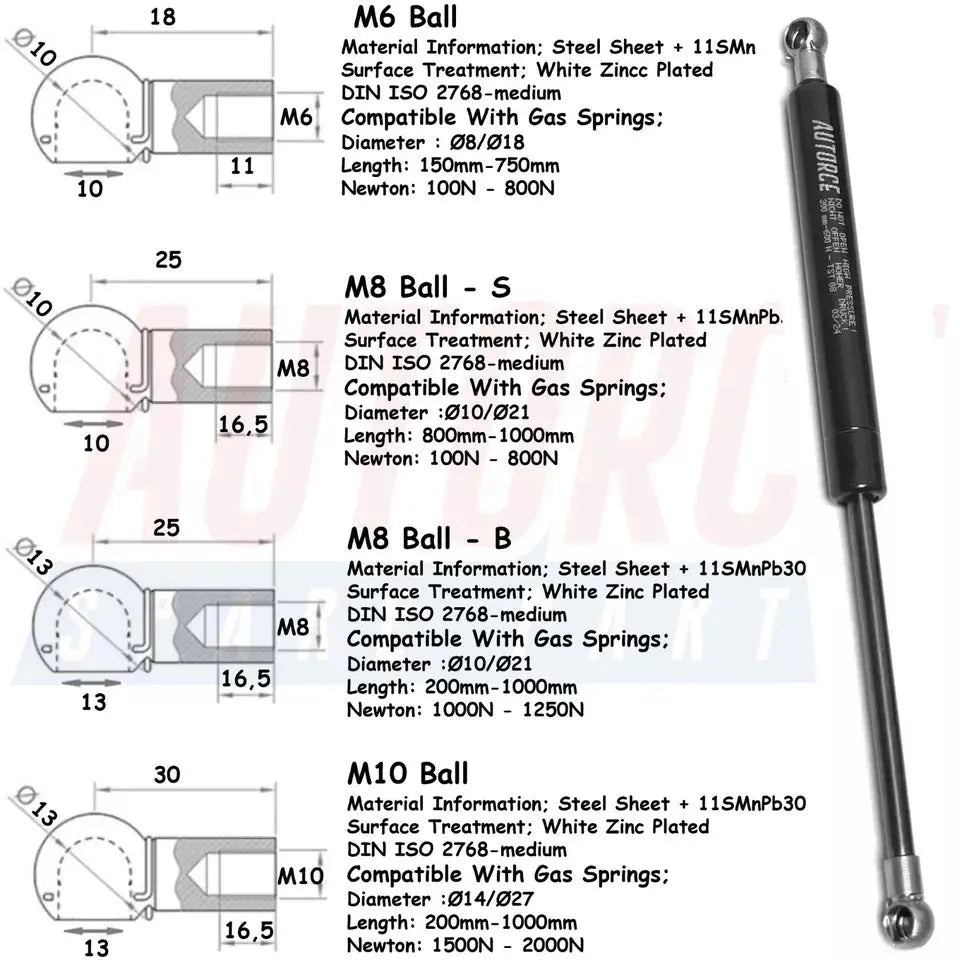

Whether you are repairing a car bonnet damper or building a custom hatch, the right fittings are crucial for a secure and smooth operation. At Autorce, we stock a comprehensive range of gas strut fittings designed to fit most UK vehicle models and universal applications. Our collection includes heavy-duty end connectors and mounting brackets compatible with standard M6, M8, and M10 thread sizes.

Replacement End Fittings (Heads)

Over time, the plastic or metal ends of a gas strut can wear out or snap, even if the strut itself is fine. Instead of replacing the whole unit, you can simply upgrade the heads. We offer:

- Ball Joint Heads (Sockets): Available in nylon plastic or durable steel. These allow the strut to pivot and angle correctly during movement.

- Eyelet Heads (Ring Fittings): Perfect for heavy-duty applications requiring a fixed, rigid connection. Typically used with pins or bolts.

- Thread Sizes: Our range covers the standard M6, M8, and M10 threads, making it easy to screw them directly onto your existing gas springs.

Mounting Brackets & Plates

If you need to install a gas strut where there is no existing mounting point, our mounting brackets are the solution. We provide:

- Ball Brackets: Flat or angled plates with integrated ball studs (10mm or 13mm balls), ideal for snapping on ball-socket struts.

- U-Type & L-Type Brackets: Robust steel brackets designed for eyelet fittings or clevis pins, offering superior strength for heavy lids and hatches.

Selecting the Right Fitting

To ensure you choose the correct part, simply check the thread size of your gas strut piston rod (usually M6, M8, or M10) and the type of connection required (Ball or Eyelet). Our gas strut fittings are manufactured to high standards, ensuring resistance to wear and the UK weather conditions.