Shop by Category

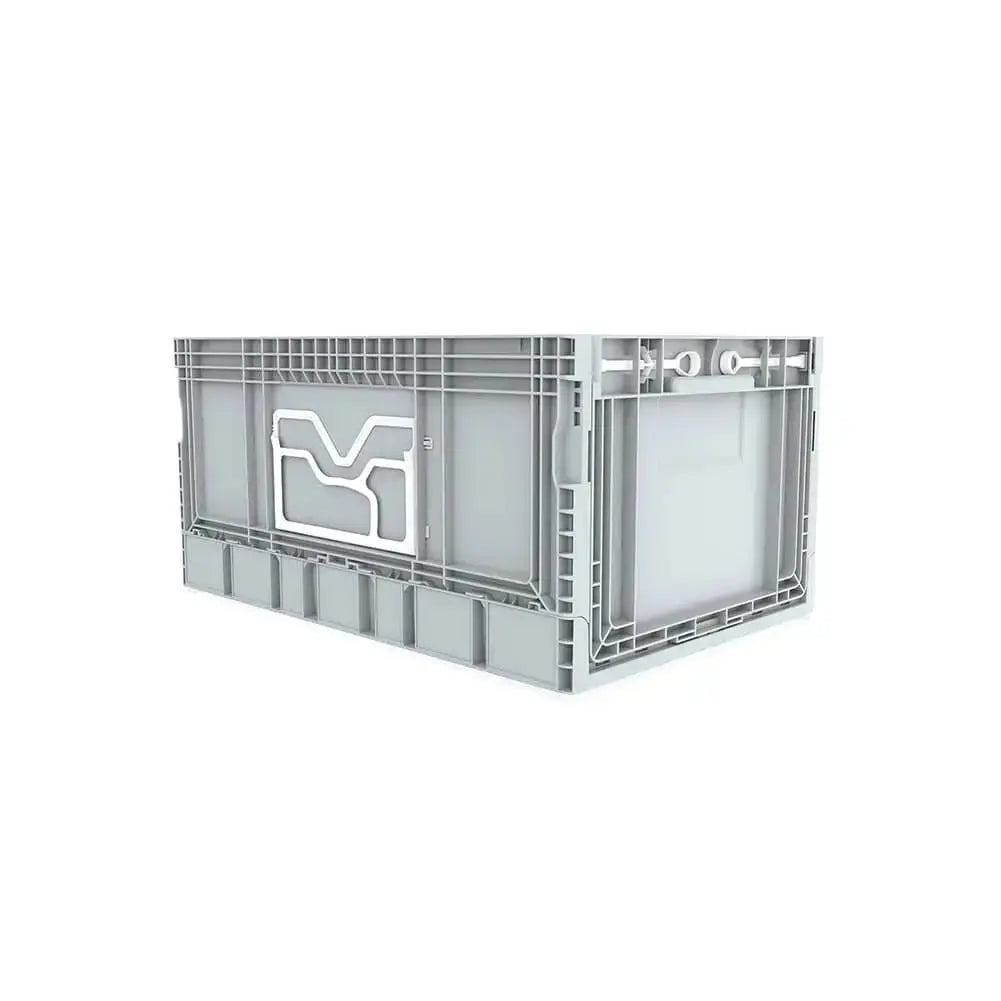

Foldable Industrial Boxes

3 products

Showing 1 - 3 of 3 products

Foldable Industrial Boxes for Efficient Storage & Return Logistics

Efficient storage and transportation solutions are essential for modern warehouses, logistics networks, and manufacturing operations. Foldable industrial boxes offer a practical and space-saving alternative to rigid containers, helping businesses reduce storage costs, optimise return logistics, and improve overall operational efficiency.

At AUTORCE, our range of foldable plastic industrial boxes is designed for durability, ease of handling, and repeated commercial use. These collapsible containers are widely used in warehousing, retail distribution, manufacturing, and closed-loop supply chains across the UK.

What Are Foldable Industrial Boxes?

Foldable industrial boxes, also known as collapsible crates, are reusable plastic containers that can be folded flat when empty. This design significantly reduces the space required for storage and return transport, making them ideal for operations where empty container handling is a key cost factor.

Key Features and Design

- Collapsible construction: Panels fold flat to minimise storage space when not in use.

- Durable plastic materials: Manufactured from HDPE or polypropylene (PP) for strength and long service life.

- Stackable when assembled: Designed to stack securely when loaded for efficient warehouse storage.

- Integrated handles: Ergonomic grips improve manual handling and workplace safety.

- Optional lids or flaps: Protect contents from dust, moisture, and contamination.

Benefits of Foldable Industrial Boxes

- Space-saving efficiency: Reduces storage requirements and transport volume for empty containers.

- Lower logistics costs: Optimised return logistics help reduce fuel, handling, and warehousing costs.

- Heavy-duty performance: Suitable for repeated industrial use and demanding supply chain environments.

- Sustainable solution: Reusable design reduces packaging waste and supports environmentally responsible operations.

Applications Across Industries

- Automotive: Transport of parts, components, and tools between facilities.

- Retail & e-commerce: Storage, order picking, and distribution in warehouses and fulfilment centres.

- Agriculture: Handling and transport of produce, plants, and equipment.

- Manufacturing: Movement of materials, work-in-progress, and finished goods.

- Pharmaceuticals: Secure storage and transport of sensitive products.

With their collapsible design, durability, and cost-saving benefits, foldable industrial boxes are an essential component of efficient modern logistics systems. They enable businesses to streamline operations, reduce environmental impact, and maintain flexibility across the supply chain.