A gas strut calculator helps you determine the correct force and mounting position for lids, hatches, and panels. Using the wrong calculation can result in poor performance, unsafe operation, or premature failure of the gas spring. This step-by-step guide explains how to calculate gas spring force accurately, avoid common mistakes, and choose the right gas strut for your application.

Whether you are working on a car boot lid, a storage box, furniture, or an industrial access panel, understanding how to use a gas strut calculator correctly will save time, reduce returns, and prevent costly errors.

Introduction to Gas Strut Calculators

Gas strut calculators simplify what would otherwise be complex mechanical calculations. Instead of relying on trial and error, these tools calculate the required gas spring force based on weight, geometry, and mounting position.

By entering a few key measurements, a gas strut calculator outputs the recommended force (usually in Newtons), helping you select the correct gas strut size. This ensures smooth opening, controlled movement, and reliable holding force.

Gas strut calculators are especially useful when:

-

The lid or panel is heavy or unevenly balanced

-

Space constraints affect mounting angles

-

Precise force control is required

What Is a Gas Spring Calculator?

A gas spring calculator is an online tool designed to calculate the force needed to lift, hold, or control a moving panel. It uses basic mechanical principles such as leverage and torque to determine the correct gas spring specification.

Typically, a gas spring calculator requires:

-

Load weight

-

Mounting geometry

-

Pivot point locations

-

Stroke length or opening angle

Once these values are entered, the calculator provides a recommended force rating and, in many cases, guidance on mounting position.

Why Calculating Gas Spring Force Matters

Correct gas spring force is critical for safety and performance. If the force is too low, the lid will not stay open. If the force is too high, the lid may open aggressively or place excessive stress on hinges and brackets.

Accurate force calculation helps to:

-

Prevent uncontrolled movement

-

Extend the lifespan of the gas strut

-

Improve user comfort and safety

Using a gas strut calculator removes guesswork and ensures the selected gas spring matches the real-world application.

Step-by-Step Guide to Calculate Gas Spring Force

Step 1: Input Basic Parameters

Begin by collecting accurate information about your application. Most gas strut calculators will ask for the following inputs:

Required Measurements

-

Weight of the lid or panel (kg)

-

Length of the lid (distance from hinge to free edge)

-

Width of the lid

-

Distance from the hinge to the centre of mass

Even small measurement errors can significantly affect the final force calculation.

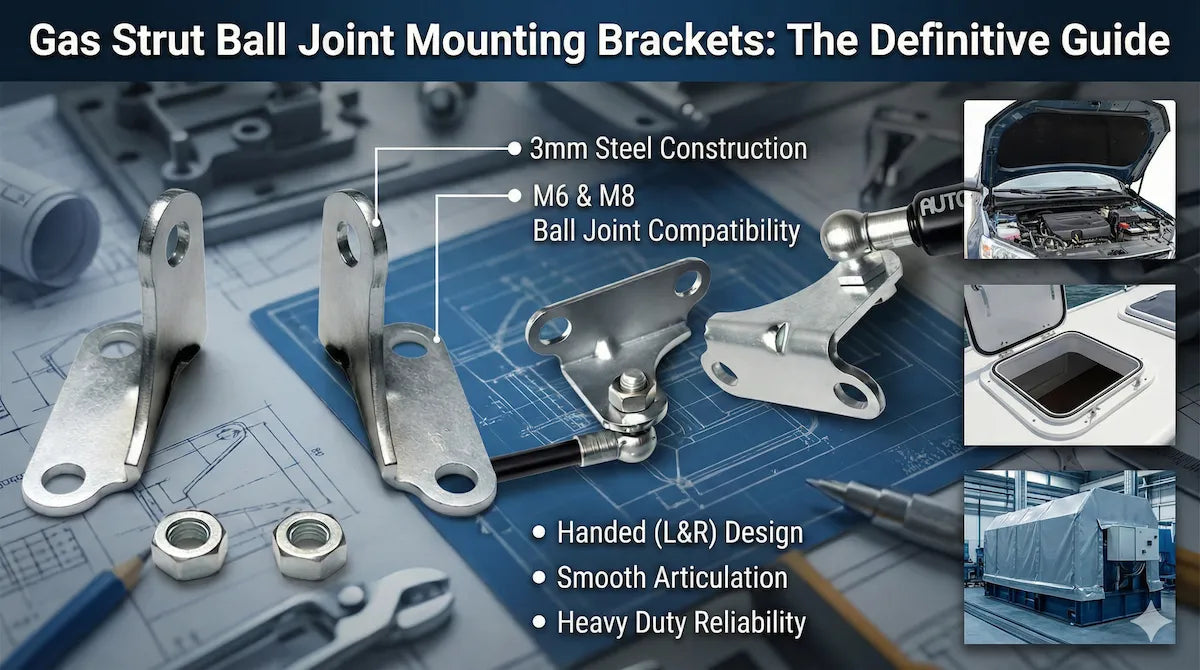

Gas Spring Mounting Position

Mounting position has a major impact on required force. You will typically need to define:

-

Upper and lower mounting points

-

Distance from the hinge

-

Approximate installation angle

Gas struts mounted closer to the hinge generally require higher Newton values.

Step 2: Calculate Gas Spring Force

Once all parameters are entered, the gas strut calculator processes the data and calculates the required force, usually displayed in Newtons (N).

At this stage, the calculator may also:

-

Suggest force ranges

-

Adjust results based on mounting position

-

Account for dual strut (pair) configurations

If two gas struts are used, the calculated force is usually shared between them.

Using the Gas Spring Force Calculator Effectively

To achieve accurate results:

-

Double-check all measurements

-

Ensure correct units are used (kg, cm, degrees)

-

Recalculate if mounting points change

Most online gas strut calculators allow real-time adjustments, making it easy to test different configurations before purchase.

Understanding Results and Graphs

Some calculators display graphs showing how force changes throughout the opening cycle. These graphs help identify:

-

Peak force points

-

Smoothness of motion

-

Whether force drops too early

If the force curve looks excessive or uneven, adjust mounting positions and recalculate.

Step 3: Final Adjustments and Selection

After reviewing the calculated force:

-

Select the nearest standard force rating

-

Confirm stroke length matches the required movement

-

Avoid excessive oversizing

A small safety margin is acceptable, but oversizing often leads to aggressive opening and unnecessary stress on fittings.

Simple Force Calculation Examples (Real-World Use)

To make gas strut calculations easier to understand, here are common real-world examples using a simple rule of thumb:

100N ≈ 10 kg of lifting force (per single gas strut)

When two gas struts are used, the total load is shared between them.

Example 1: Car Boot / Tailgate

Scenario

-

Boot lid weight: approx. 40 kg

-

Number of gas struts: 2

Calculation

-

40 kg ÷ 2 = 20 kg per strut

-

20 kg ≈ 200N

Recommended setup:

2 × 200N gas struts

If struts are mounted close to the hinge, a higher force (e.g. 250N) may be required.

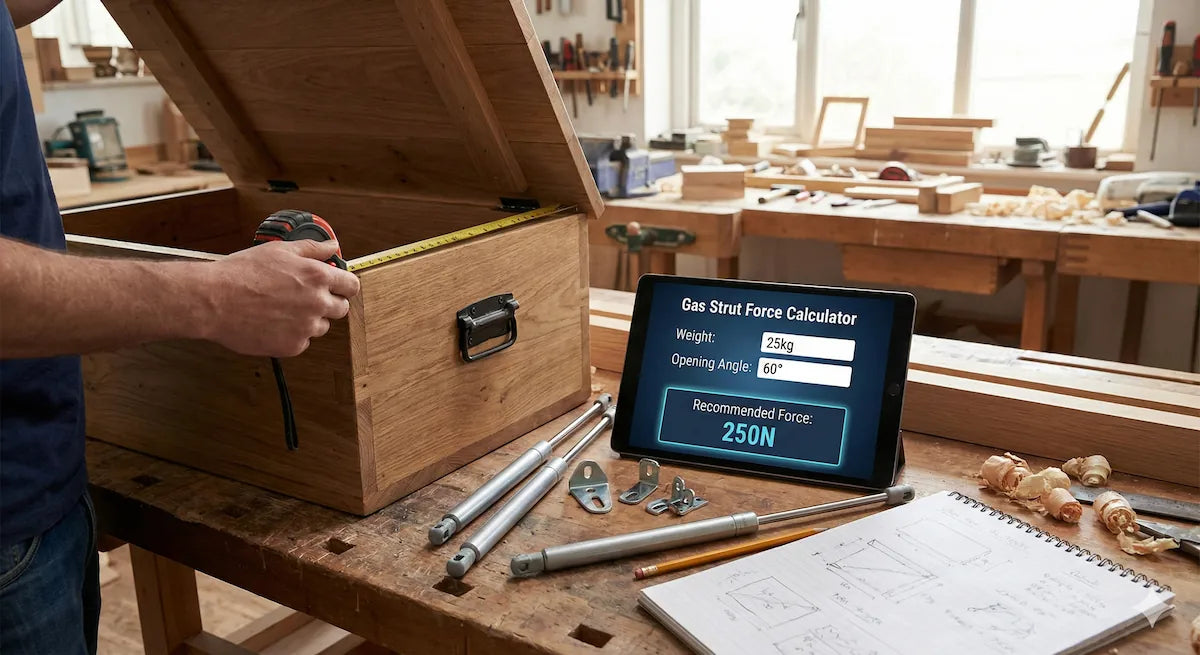

Example 2: Storage Box or Chest Lid

Scenario

-

Wooden lid weight: approx. 25 kg

-

Number of gas struts: 1

Calculation

-

25 kg ≈ 250N

Recommended setup:

1 × 250N gas strut

For a softer opening motion, a 200N strut may also be suitable.

Example 3: Furniture Lid or Bed Base

Scenario

-

Lid weight: approx. 30 kg

-

Number of gas struts: 2

Calculation

-

30 kg ÷ 2 = 15 kg per strut

-

15 kg ≈ 150N

Recommended setup:

2 × 150N gas struts

Choosing the Right Gas Strut After Calculation

After determining the required force, selecting the correct gas strut also depends on:

-

Stroke length

-

Extended and compressed lengths

-

Material and corrosion resistance

Matching these specifications ensures proper fit and long-term reliability.

Common Mistakes When Using a Gas Strut Calculator

Even with a calculator, mistakes can occur. The most common issues include:

-

Incorrect mounting angle

-

Ignoring weight distribution

-

Oversizing the gas strut force

-

Forgetting that force is shared when using two struts

Avoiding these mistakes improves safety and overall performance.

Common Uses of Gas Strut Calculators

Automotive Applications

Used for bonnets, tailgates, and boot lids to ensure controlled opening and safe holding force.

Furniture Design

Applied in lift-up beds, storage units, and adjustable furniture for ergonomic movement.

Industrial Machinery

Essential for access panels, machine guards, and service covers requiring controlled motion.

Conclusion

A gas strut calculator is an essential tool for selecting the correct gas strut force and mounting position. By following a structured, step-by-step approach, you can avoid common mistakes, improve safety, and ensure smooth operation.

Before purchasing gas struts, always verify your calculations using a reliable gas strut calculator. Accurate planning at this stage saves time, reduces costs, and results in a better-performing final product.

Frequently Asked Questions

How accurate is a gas strut calculator?

A gas strut calculator is highly accurate when correct measurements and mounting positions are used. Incorrect inputs are the most common cause of wrong results.

How many Newtons do I need for my gas strut?

As a general rule, 100N is approximately equal to 10 kg of lifting force per gas strut. When using two struts, the load is shared between them.

Is 100N really equal to 10 kg?

Yes, this is a commonly used rule of thumb for gas struts. However, mounting position and angle can increase or reduce the required force.

Should I use one or two gas struts?

Larger or wider lids usually require two gas struts for stability and even load distribution. Smaller lids may work with a single strut.