Industrial Storage Boxes for Automotive and Logistics | Durable Plastic Solutions

Industrial storage boxes are essential components of modern manufacturing, warehousing, and logistics operations. Designed for heavy-duty use, long-term durability, and operational efficiency, these boxes provide safe and organised transport and storage across multiple industries.

Industrial Storage Boxes for Durable and Sector-Specific Solutions

Industrial plastic boxes are professional-grade containers engineered to withstand demanding industrial environments. Unlike standard plastic containers, they are built for continuous circulation, stacking under load, and automated logistics systems.

They are widely used in:

- Manufacturing plants

- Automotive production lines

- Logistics and distribution centres

- Chain supermarkets

- Electronics, hardware and chemical industries

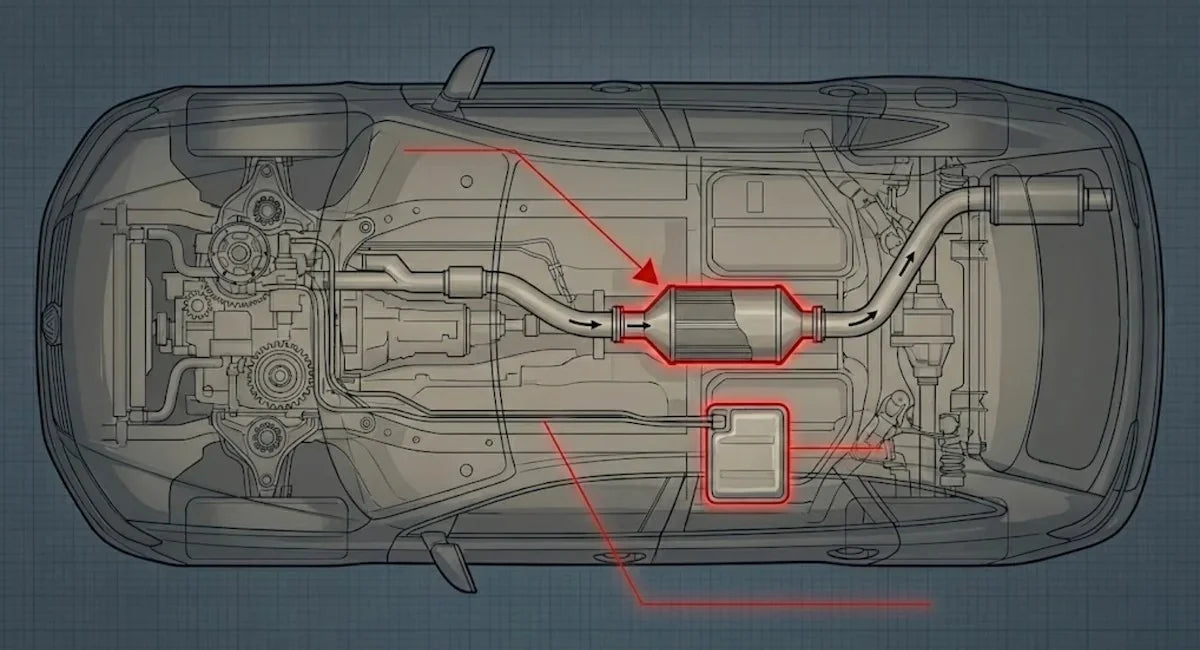

Automotive Industry Applications

The automotive sector requires robust, modular and reliable storage solutions due to its vast product range and strict quality standards.

Our industrial boxes for automotive logistics are designed to safely transport:

- Small fasteners and components

- Medium-sized mechanical parts

- Heavy automotive assemblies

These boxes are commonly used throughout the entire supply chain, from component suppliers to final assembly lines.

Structural Strength and Stackability

Thanks to their fully closed side walls and reinforced base structure, industrial boxes can be stacked safely without damaging products on lower levels.

- Secure vertical storage

- Efficient use of warehouse space

- Long-term shelf storage without deformation

Industrial Box Types and Configurations

Industrial storage boxes can be manufactured in multiple configurations to meet sector-specific needs:

- VDA-KLT Industrial Boxes and Lids

- Standard Euro Industrial Boxes

- Foldable Industrial Boxes

- Active and Passive Lock Foldable Boxes

- Attached Lid Containers ALC

- Bale Arm Crates

Explore our collections:

- Standard Euro Industrial Boxes

- Foldable Industrial Boxes

- Attached Lid Containers ALC

- Bale Arm Crates

Medium and Heavy Load Performance

Designed for medium and heavy-duty loads, industrial plastic boxes maintain structural integrity even under continuous stress.

This makes them a long-term investment rather than a disposable packaging solution.

Compatibility with Conveyor Systems

With their stable and flat base design, industrial boxes are fully compatible with:

- Automated conveyor systems

- Production lines

- Sorting and handling equipment

This ensures uninterrupted material flow across production and logistics operations.

ESD Conductive Industrial Boxes

In addition to standard PPC raw material, industrial boxes can be produced with ESD conductive additives.

- Protect sensitive electronic components

- Prevent electrostatic discharge

- Reduce explosion and short-circuit risks

Traceability and Customisation Options

To enhance traceability and stock control, industrial boxes can be customised with:

- Screen or laser printing

- Sequential numbering

- Hot stamping

- RFID labels

- PVC or plastic card holders

These features support efficient inventory management and digital tracking systems.

Hygiene Washability and Food Safety

All industrial boxes are washable and reusable, making them suitable for industries with strict hygiene standards.

- Washed in industrial washing machines

- Sterilised after each use

- Produced with 100 percent food-safe materials

Sustainability and Recycled Materials

Sustainability is a key advantage of modern industrial storage systems.

- Circular economy models

- Reduced carbon footprint

- Long product lifecycle

Using recycled and environmentally friendly raw materials, industrial boxes can be produced in different colours and material qualities without compromising performance.

Industrial storage boxes are not just containers — they are strategic tools for efficiency safety and sustainability across the entire supply chain.

Frequently Asked Questions

What are industrial storage boxes used for?

Industrial storage boxes are used for the safe transport, handling and storage of components in manufacturing, automotive, logistics and warehouse environments. They are designed to withstand heavy loads, repeated use and automated handling systems.

Are industrial plastic boxes suitable for heavy-duty use?

Yes. Industrial plastic boxes are specifically engineered for medium and heavy-duty applications. Their reinforced base structure and closed side walls allow them to carry heavy loads without deformation, even when stacked.

Can industrial storage boxes be used on conveyor systems?

Most industrial storage boxes are fully compatible with conveyor and automation systems. Their flat and stable base design ensures smooth movement on production lines, sorting systems and automated warehouses.

What is the difference between standard and ESD conductive industrial boxes?

Standard industrial boxes are made from PPC plastic for general use. ESD conductive boxes include special additives that prevent electrostatic discharge, making them ideal for electronics, sensitive components and explosion-risk environments.

Are industrial storage boxes reusable and recyclable?

Yes. Industrial storage boxes are designed for long-term reuse and can be washed, sterilised and returned to circulation. Many models are produced using recycled raw materials and are fully recyclable at the end of their lifecycle.

Which industries commonly use industrial storage boxes?

Industrial storage boxes are widely used in automotive manufacturing, logistics and distribution centres, electronics production, chain supermarkets, food processing and chemical industries.