What Is a Gas Strut Ball Joint Mounting Bracket?

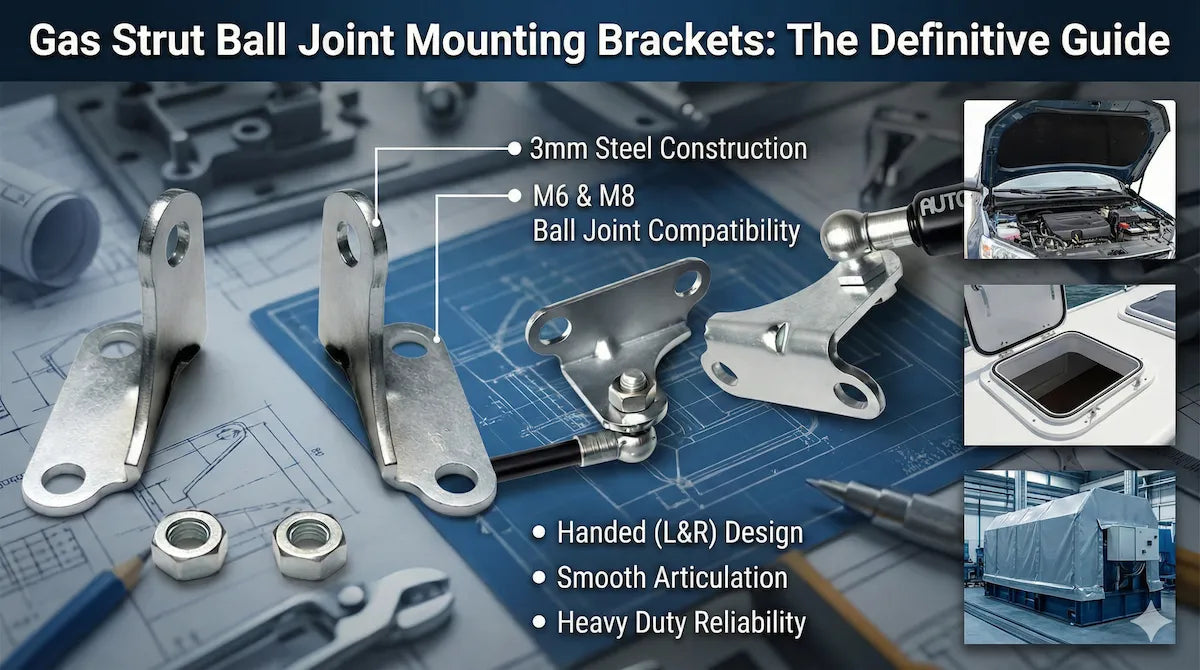

A gas strut ball joint mounting bracket is a metal fixing component designed to securely attach gas struts (also known as gas springs) to a surface using a ball-and-socket connection. This type of mounting allows controlled movement while maintaining strength, alignment and reliability under load.

Ball joint brackets are commonly used in automotive, marine, caravan and industrial applications where smooth opening and closing motion is essential.

Why Ball Joint Mounting Is Preferred for Gas Struts

Smooth Articulation and Controlled Movement

Ball joint connections allow controlled multi-directional movement, which reduces stress on both the gas strut rod and the mounting points. This design helps prevent binding, uneven wear and premature failure during operation.

Reduced Stress on Mounting Points

Compared to rigid mounting solutions, ball joint brackets compensate for minor alignment variations during installation and use. This flexibility improves long-term durability and ensures consistent performance.

Heavy Duty vs Standard Gas Strut Brackets

Why 3mm Steel Makes a Difference

Many standard gas strut brackets are manufactured from 1.5mm or 2mm steel. While suitable for light-duty applications, thinner brackets can deform over time when exposed to higher gas spring forces or frequent operation.

Heavy duty brackets manufactured from 3mm thick steel offer significantly higher resistance to bending, fatigue and long-term deformation, making them suitable for demanding applications.

Reinforced Design for Long-Term Durability

Reinforced embossing at high-stress areas increases structural rigidity and helps distribute load more evenly across the bracket. This design feature plays a critical role in maintaining alignment and extending service life.

M6 and M8 Ball Joint Compatibility Explained

Understanding Ball Stud Sizes

M6 and M8 refer to the thread size of the ball stud used with the gas strut. Brackets designed to accommodate both sizes provide greater installation flexibility and compatibility with a wider range of gas struts.

Benefits of Dual Compatibility

Supporting both M6 and M8 ball joints allows easier replacements, simplifies future upgrades and reduces the need for multiple bracket types. This is particularly beneficial for workshops, installers and DIY users.

Why Handed (Left & Right) Design Offers Better Fit

Precision Fit for Professional Installations

In many applications, precise alignment is essential for smooth operation and long-term reliability. Handed (left and right) mounting brackets are engineered to follow the natural geometry of the installation surface, providing a more accurate and stable fit.

Improved Load Distribution and Alignment

Asymmetric bracket designs help distribute load more evenly across mounting points and reduce torsional stress on the gas strut. This results in smoother movement, reduced wear and improved system performance over time.

Preferred Solution for Controlled Applications

Rather than relying on a one-size-fits-all approach, left and right-specific brackets are commonly used in professional automotive, marine and industrial installations where clearance, mounting angle and alignment are critical.

Common Applications for Gas Strut Ball Joint Brackets

Automotive Applications

- Bonnet and hood supports

- Boot and tailgate systems

- Engine covers and access panels

Marine and Caravan Installations

- Hatch covers

- Storage compartments

- Service and access doors

Industrial and Custom Projects

- Toolboxes and storage lids

- Machinery covers

- Custom fabrications and conversions

Choosing Between 2 Pack and 4 Pack Sets

When a 2 Pack Is the Right Choice

A 2 pack set is ideal for single gas strut installations, replacements or compact applications where minimal hardware is required.

Advantages of a 4 Pack Set

A 4 pack set is recommended for dual gas strut systems, symmetrical installations or projects requiring consistent mounting across multiple panels.

Installation Tips for Optimal Performance

Prepare the Mounting Surface

Ensure the mounting surface is clean, flat and structurally sound. A solid foundation is essential for proper bracket performance and long-term safety.

Use Appropriate Fasteners

Always use suitable fasteners and locking nuts to prevent loosening over time. Correct torque application helps maintain secure mounting.

Test Movement Before Final Tightening

Before fully tightening all fixings, cycle the gas strut through its full range of motion to confirm smooth operation and correct alignment.

Conclusion: A Reliable Solution for Demanding Applications

Heavy duty gas strut ball joint mounting brackets manufactured from 3mm steel provide a strong, reliable and professional solution for a wide range of applications.

With reinforced construction, M6 and M8 compatibility and precision left and right design, these brackets deliver long-term durability, smooth operation and dependable performance.

Choosing properly engineered mounting hardware ensures safer operation, reduced wear and extended service life for your gas strut system.

Frequently Asked Questions About Gas Strut Ball Joint Brackets

What is the advantage of using a ball joint bracket for gas struts?

Ball joint brackets allow controlled multi-directional movement, which reduces stress on both the gas strut and the mounting points. This results in smoother operation, better alignment and longer service life compared to rigid mounting solutions.

Are 3mm steel gas strut brackets really stronger than standard brackets?

Yes. Brackets manufactured from 3mm thick steel offer significantly higher resistance to bending and deformation compared to standard 1.5mm or 2mm brackets. This makes them ideal for heavy-duty and high-load applications.

What does M6 and M8 compatibility mean for gas strut brackets?

M6 and M8 refer to the thread size of the ball stud used with the gas strut. Brackets compatible with both sizes provide greater flexibility, allowing the use of different gas struts without changing the mounting hardware.

Why are some gas strut brackets designed as left and right specific?

Handed (left and right) brackets are engineered to follow the natural geometry of the installation surface. This improves alignment, load distribution and overall system stability, especially in professional automotive and marine applications.

Are ball studs included with gas strut mounting brackets?

In most cases, ball studs are not included. Brackets are typically supplied with locking nuts only, allowing installers to select the appropriate ball stud length and thread size for their specific application.