How to Choose the Right Gas Strut: A Complete Guide for UK Buyers

Choosing the correct gas strut is essential for safe operation, smooth movement, and long-term reliability. Selecting the wrong force, length, or fitting can lead to poor performance, premature wear, or even safety risks.

This guide explains how gas struts work, which measurements matter most, and how to confidently choose the right gas strut for automotive, furniture, marine, and domestic applications across the UK.

What Is a Gas Strut?

A gas strut (also known as a gas spring) is a sealed mechanical component that uses compressed nitrogen gas to provide controlled lifting and support. Gas struts are widely used in applications such as car boot lids, ottoman beds, cabinets, hatches, and machinery covers.

Unlike traditional springs, gas struts deliver smooth and consistent force throughout their movement, helping heavy panels open easily and remain safely supported.

Why Choosing the Correct Gas Strut Matters

Incorrect gas strut selection is one of the most common causes of operational problems. Typical issues include:

- Underpowered struts: Panels fail to stay open or drop unexpectedly

- Overpowered struts: Panels become difficult to close or open too aggressively

- Incorrect length: Limited opening angle or installation failure

- Wrong end fittings: Mounting incompatibility

Selecting the correct specification from the start prevents returns, installation issues, and unnecessary wear.

The Three Key Measurements You Need

1. Force Rating (Newtons)

The force rating, measured in Newtons (N), determines how much lifting power the gas strut provides. This must be strong enough to hold the panel open, but not so strong that closing becomes difficult.

The required force depends on:

- Panel or lid weight

- Distance from hinge to mounting point

- Opening angle

- Number of gas struts used (usually a pair)

Because mounting geometry has a major impact on force requirements, calculating this manually can be misleading. Using a dedicated gas strut calculator ensures accurate results.

2. Extended Length

The extended length is the distance between mounting centres when the gas strut is fully open. This measurement determines how far the panel can open.

If replacing an existing gas strut, measure it fully extended from centre to centre, including end fittings.

3. Compressed Length (Stroke)

The compressed length is the distance between mounting centres when the gas strut is fully closed. The difference between extended and compressed length is known as the stroke.

Ensuring adequate clearance when fully closed prevents mechanical interference and damage.

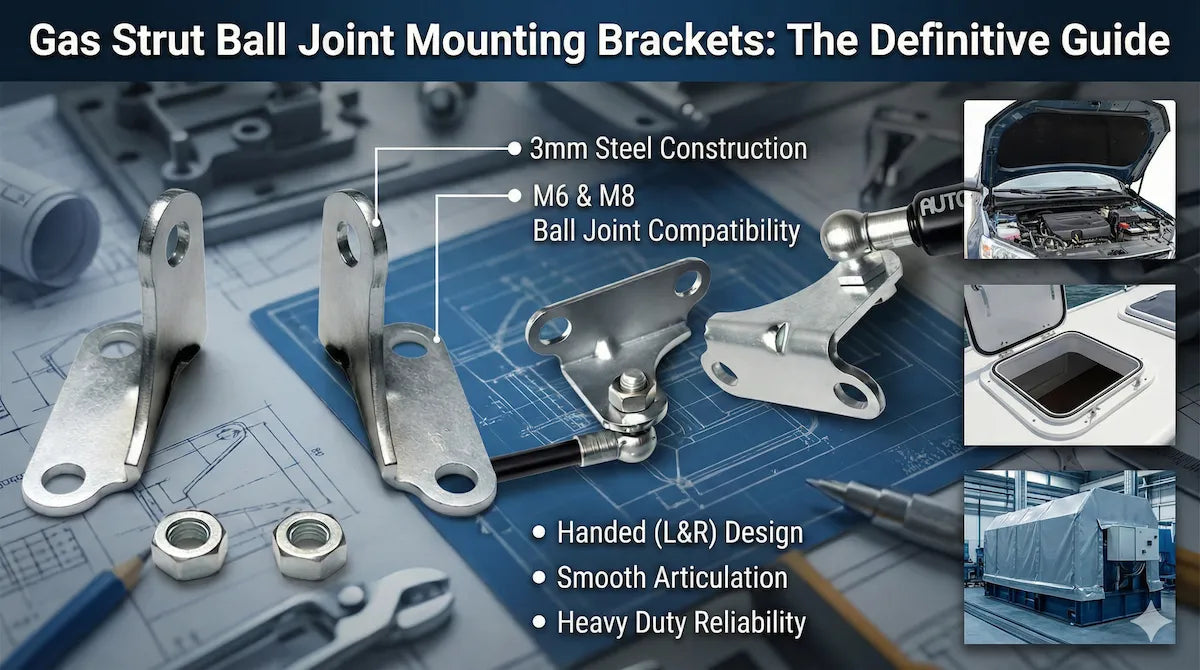

Understanding End Fittings

Gas struts are available with different end fittings depending on application requirements:

- Ball sockets (8mm or 10mm): Most common and flexible option

- Eye ends: Secure bolted connection

- Threaded studs: Direct mounting into threaded brackets

For most UK applications, ball socket fittings provide the easiest installation and alignment flexibility.

Typical UK Applications and Force Ranges

The values below are general guidance only. Always calculate for your specific setup.

- Car boot lids: 200–600N per strut (pair)

- Kitchen cabinet doors: 60–150N per strut (pair)

- Ottoman beds (single): 400–800N per strut (pair)

- Ottoman beds (double / king): 800–1200N per strut (pair)

- Caravan hatches: 100–300N per strut (pair)

- Marine engine covers: 150–400N per strut (pair)

Installation Guidance

- Support the panel securely before removal or installation

- Install the lower mounting point first

- Fit with correct orientation (rod pointing downward where possible)

- Test movement slowly before normal use

Important: Gas struts are pressurised components. Never drill, cut, or disassemble them.

How Long Do Gas Struts Last?

High-quality gas struts typically last between 5–10 years depending on load, usage frequency, and environmental conditions.

Signs replacement may be required include:

- Panel no longer stays open

- Visible oil leakage

- Inconsistent or jerky movement

Final Thoughts

Choosing the right gas strut does not need to be complicated. Accurate measurements and proper force calculation are the key to safe and reliable performance.

For fast and accurate results, use our calculator before ordering: