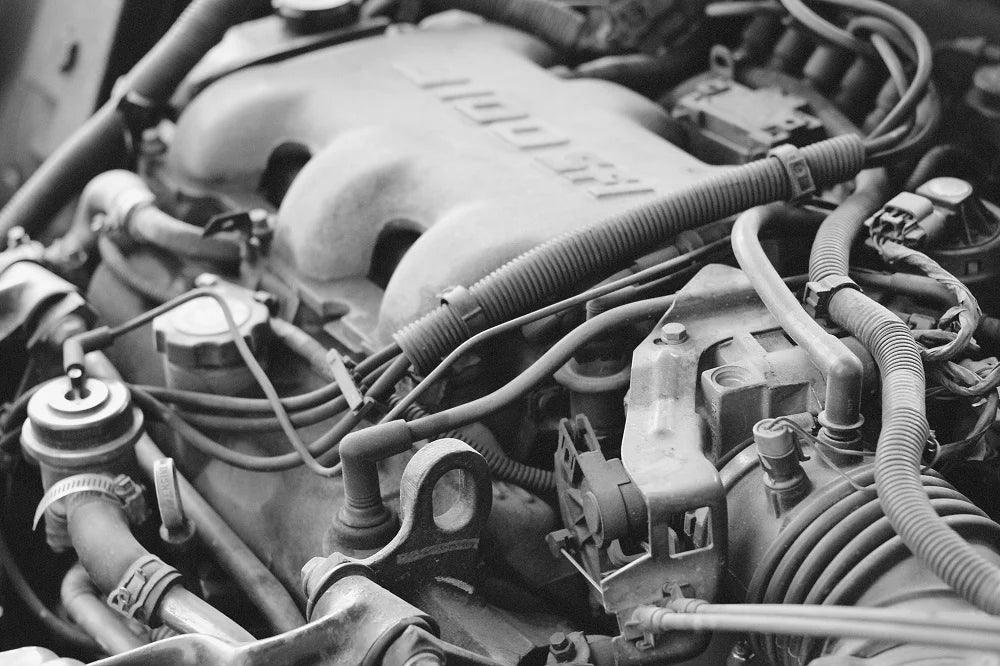

Key Engine Components Explained

Engines are the beating heart of modern transportation, powering cars, aircraft, ships, and industrial machinery. They convert energy into mechanical motion, enabling vehicles and equipment to operate efficiently.

To achieve this, an engine relies on multiple engine components working together in perfect coordination. This guide explains the key engine parts and their roles in smooth, reliable operation.

Cylinder Block

The cylinder block, often referred to as the engine block, forms the structural foundation of an internal combustion engine. It houses the cylinders, pistons, and many critical internal components.

Typically made from cast iron or aluminium alloy, the cylinder block also contains passages for coolant, oil, and exhaust gases. It must withstand extreme pressure and heat generated during engine operation.

Pistons and Connecting Rods

Pistons move up and down inside the cylinders and convert combustion energy into linear motion.

Connecting rods link the pistons to the crankshaft, transferring this motion and enabling rotational movement. Pistons are commonly made from aluminium alloy due to their lightweight and heat-dissipating properties.

Crankshaft

The crankshaft converts the reciprocating motion of the pistons into rotational motion. As pistons move, they apply force to the crankshaft, causing it to rotate.

This rotational energy is then transferred to the transmission and drivetrain, ultimately powering the vehicle.

Valvetrain

The valvetrain controls airflow into and out of the engine. It includes valves, camshafts, and related components.

Camshafts regulate valve timing, ensuring the correct air-fuel mixture enters the cylinders and exhaust gases exit efficiently. Engine designs may use overhead camshafts (OHC) or pushrod systems.

Fuel Injection System

Modern engines use a fuel injection system to deliver precise amounts of fuel into the combustion chamber.

Fuel injectors, controlled by the engine’s ECU, spray fuel in a fine mist to improve combustion efficiency, reduce emissions, and enhance performance. Fuel injection systems have largely replaced carburettors in modern vehicles.

Cooling System

The engine cooling system prevents overheating and maintains optimal operating temperature.

It consists of a radiator, water pump, thermostat, and coolant. Coolant absorbs heat from the engine and releases it through the radiator, while the thermostat regulates flow to maintain stable temperatures.

Lubrication System

The lubrication system reduces friction and wear between moving engine components.

Engine oil forms a protective film between parts, preventing metal-to-metal contact. Key components include the oil pump, oil filter, and oil pan, all working together to maintain oil circulation and cleanliness.

Conclusion

Engine components work together to transform energy into mechanical power efficiently and reliably. From the cylinder block to the valvetrain, fuel injection, cooling, and lubrication systems, each part plays a critical role.

As engine technology continues to evolve, these components are becoming more efficient, durable, and environmentally friendly.

Frequently Asked Questions

What are the main components of an engine?

The main engine components include the cylinder block, pistons, connecting rods, crankshaft, valvetrain, fuel injection system, cooling system, and lubrication system.

What is the role of the crankshaft?

The crankshaft converts the up-and-down motion of the pistons into rotational motion that powers the vehicle.

Why is engine lubrication important?

Lubrication reduces friction and wear between moving parts, helping prevent overheating and extending engine life.

How does the cooling system protect the engine?

The cooling system regulates engine temperature by removing excess heat, preventing overheating and mechanical damage.