Injector Nozzle

57 products

Showing 1 - 24 of 57 products

The Crucial Role of Injector Nozzles in Modern Car Engines

In the ever-evolving world of automotive technology, the injector nozzle stands as a testament to the remarkable advancements in fuel delivery systems. The injector nozzle, a seemingly small component, plays a crucial role in the operation and performance of modern car engines. In this article, we will delve into the significance of injector nozzles, their function, types, and the impact they have on fuel efficiency and emissions in contemporary automobiles.The Function of Injector Nozzles

At the heart of the fuel injection system lies the injector nozzle. Its primary function is to atomize the fuel and deliver it to the engine's combustion chamber in a highly pressurized, finely dispersed spray. Unlike older carbureted engines that relied on a venturi effect, modern vehicles employ electronic fuel injection (EFI) systems that utilize injector nozzles for precise fuel delivery.Injector nozzles are controlled by the car's engine control unit (ECU), which constantly monitors various parameters such as engine load, RPM, and throttle position to determine the ideal amount of fuel to inject. This process ensures optimum fuel-air mixture ratios for efficient combustion and maximum power output.

Types of Injector Nozzles

1. Port Fuel Injector: This common type of injector nozzle is located in the intake manifold near the intake valve of each cylinder. It sprays fuel directly onto the back of the intake valve, allowing for better mixing of air and fuel before entering the combustion chamber. Port fuel injectors are widely used in multi-point fuel injection (MPFI) systems.2. Direct Fuel Injector: As the name suggests, direct fuel injectors deliver fuel directly into the combustion chamber, bypassing the intake manifold. This design provides better control over the fuel-air mixture and allows for a more efficient burn. Direct injection is commonly found in modern gasoline and diesel engines.

3. Common Rail Injector: This type of injector is predominantly used in diesel engines. The common rail system stores high-pressure fuel in a common rail, from which individual injectors draw the required amount of fuel for each cylinder. This approach enables precise fuel delivery and reduces emissions, making diesel engines more environmentally friendly.

Impact on Fuel Efficiency and Emissions

The efficiency and precision of injector nozzles significantly impact a car's fuel economy and emissions performance. Properly functioning injector nozzles ensure that the engine receives the right amount of fuel, preventing fuel wastage and optimizing combustion. As a result, the vehicle achieves better mileage and reduces its carbon footprint.Clogged or malfunctioning injector nozzles can lead to poor atomization of fuel, resulting in incomplete combustion. This can lead to decreased fuel efficiency, reduced power output, and increased emissions of harmful pollutants like carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbons (HC). Regular maintenance and cleaning of injector nozzles are essential to keep the engine running smoothly and efficiently.

The injector nozzle may be a small and inconspicuous component, but it plays a vital role in ensuring the smooth operation, fuel efficiency, and emission compliance of modern car engines. As automotive technology continues to advance, the development of more efficient and precise injector nozzles will remain crucial to meeting the demands for cleaner and more economical vehicles. With ongoing research and innovation, these tiny components will continue to be at the forefront of driving the automotive industry towards a greener and more sustainable future.

Showing 1 - 24 of 57 products

Display

View

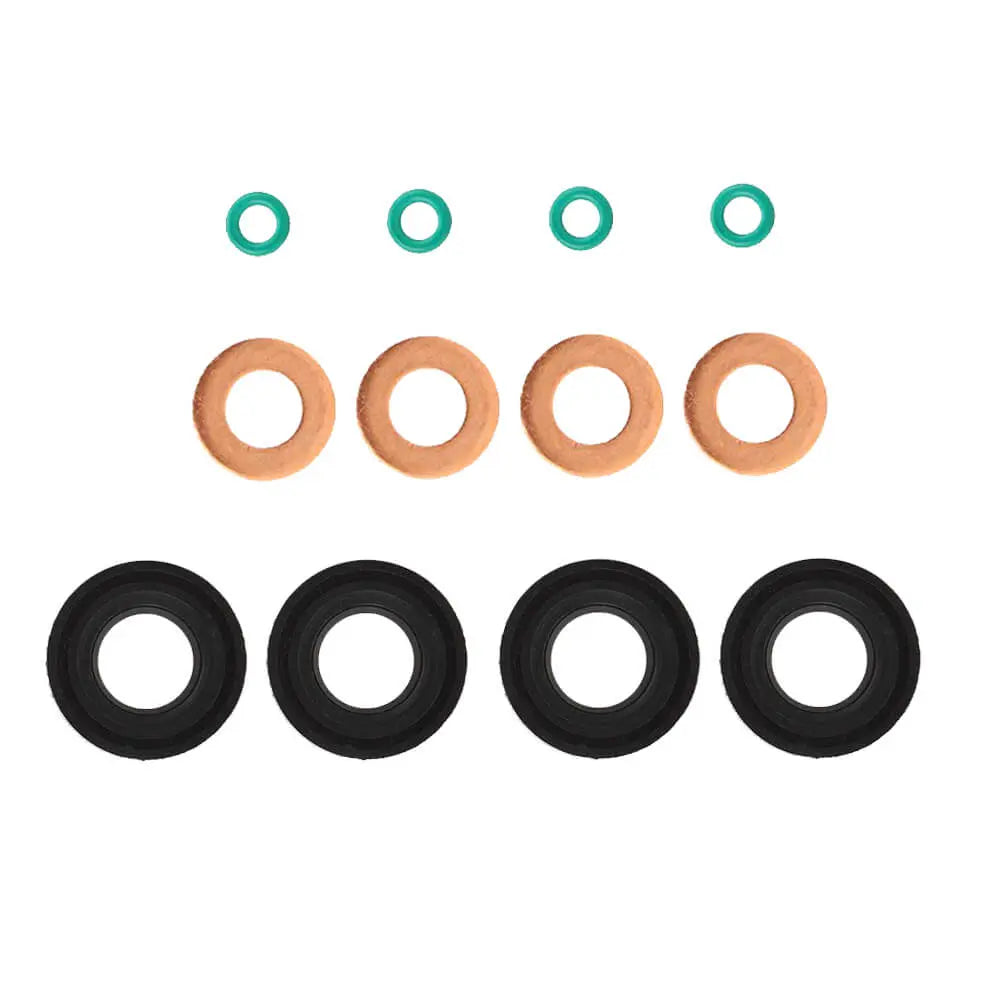

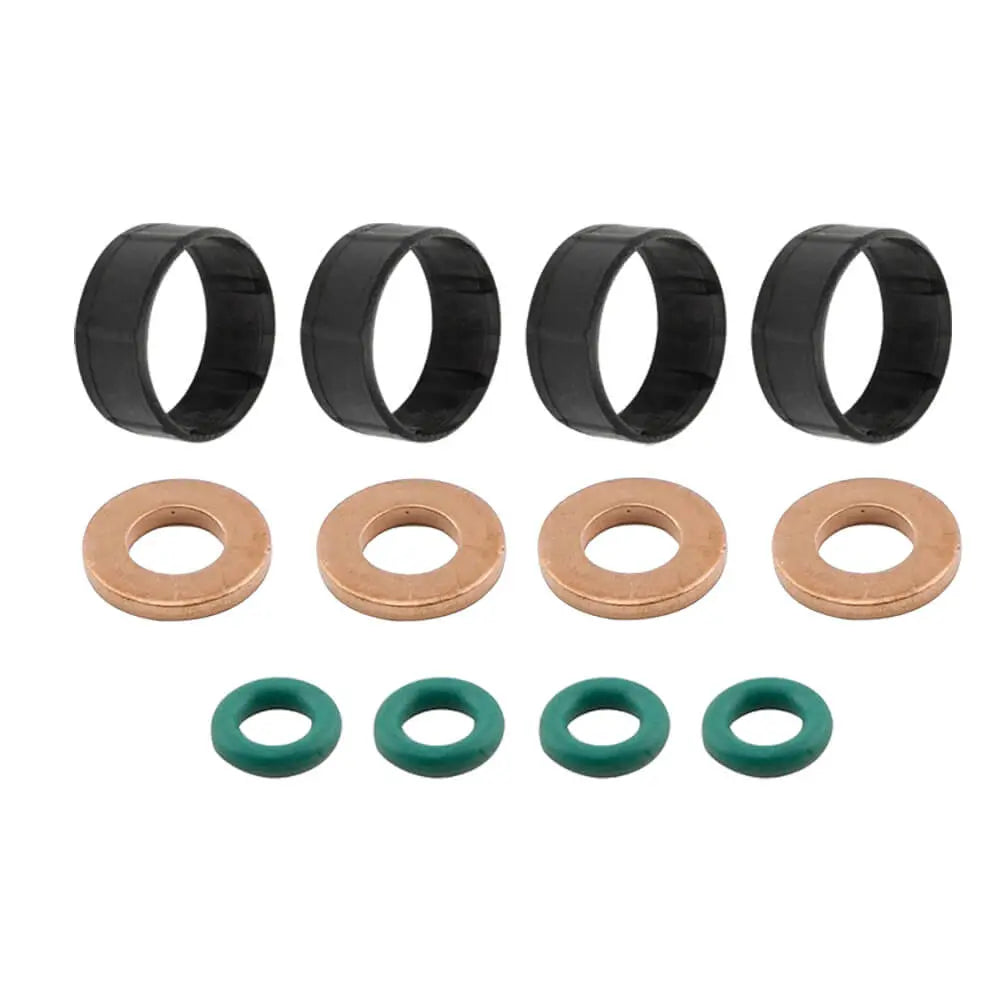

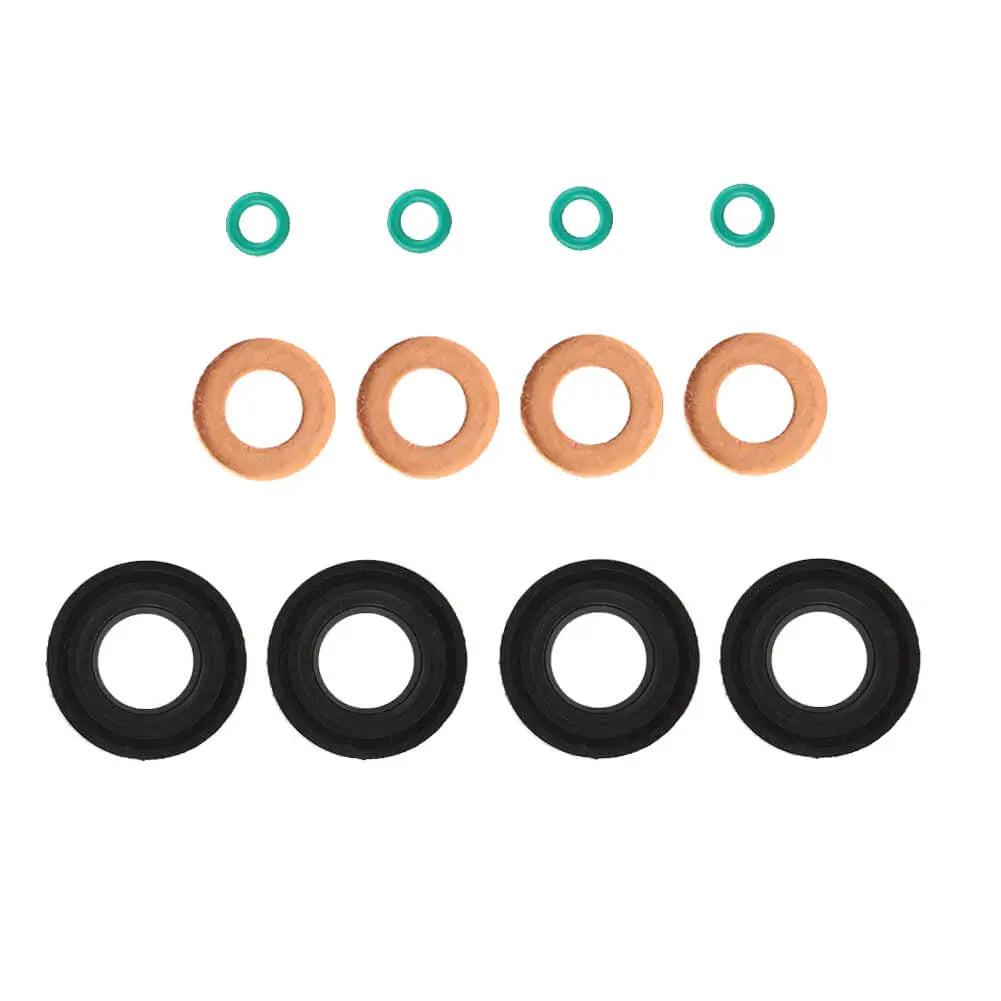

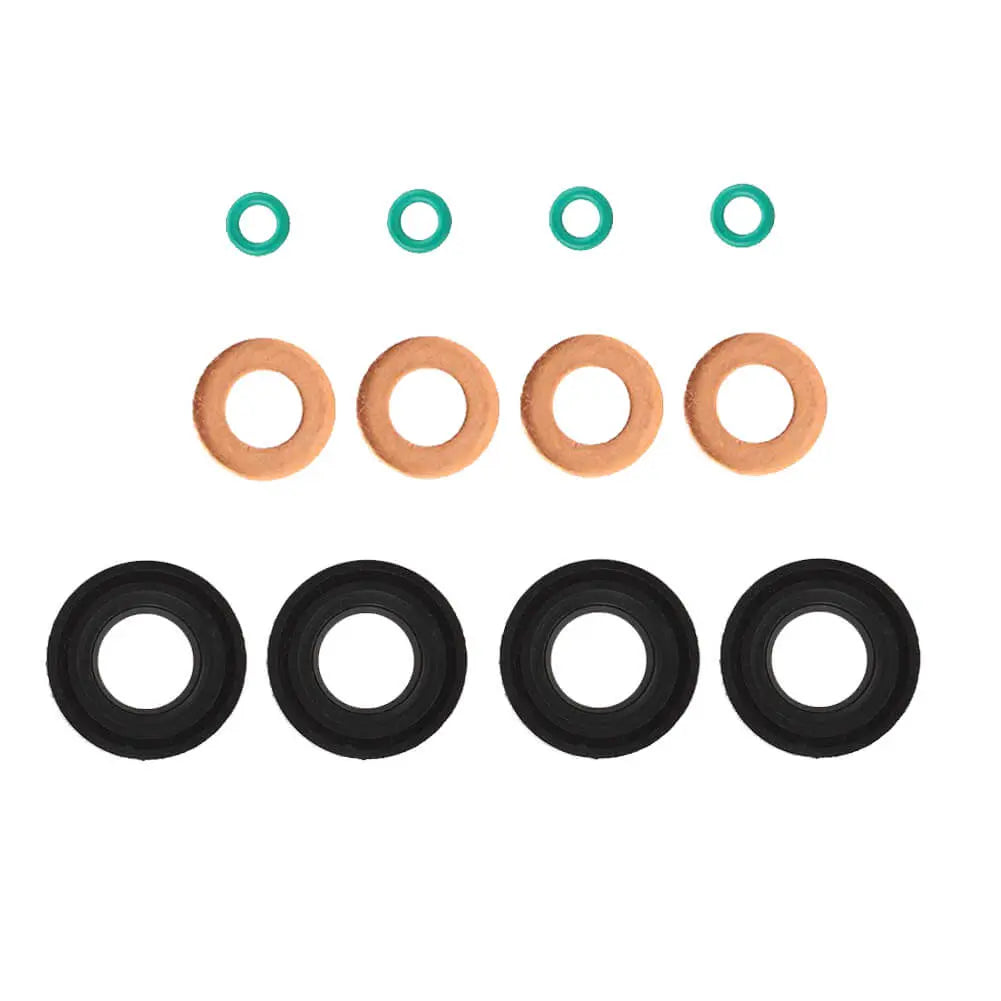

Fuel Injector Seal Washer O-Ring Set For VW Beetle Caddy Golf Plus Golf VI Jetta Passat Polo Touran - 03L103070A

In stock, 49 units

Sale price£11.49

Fuel Injector Seal Washer O-Ring Set For Seat Altea Leon Ibiza Toledo (2009 - Onwards) 03L103070A, BK2Q9M577AA

In stock, 49 units

Sale price£11.49

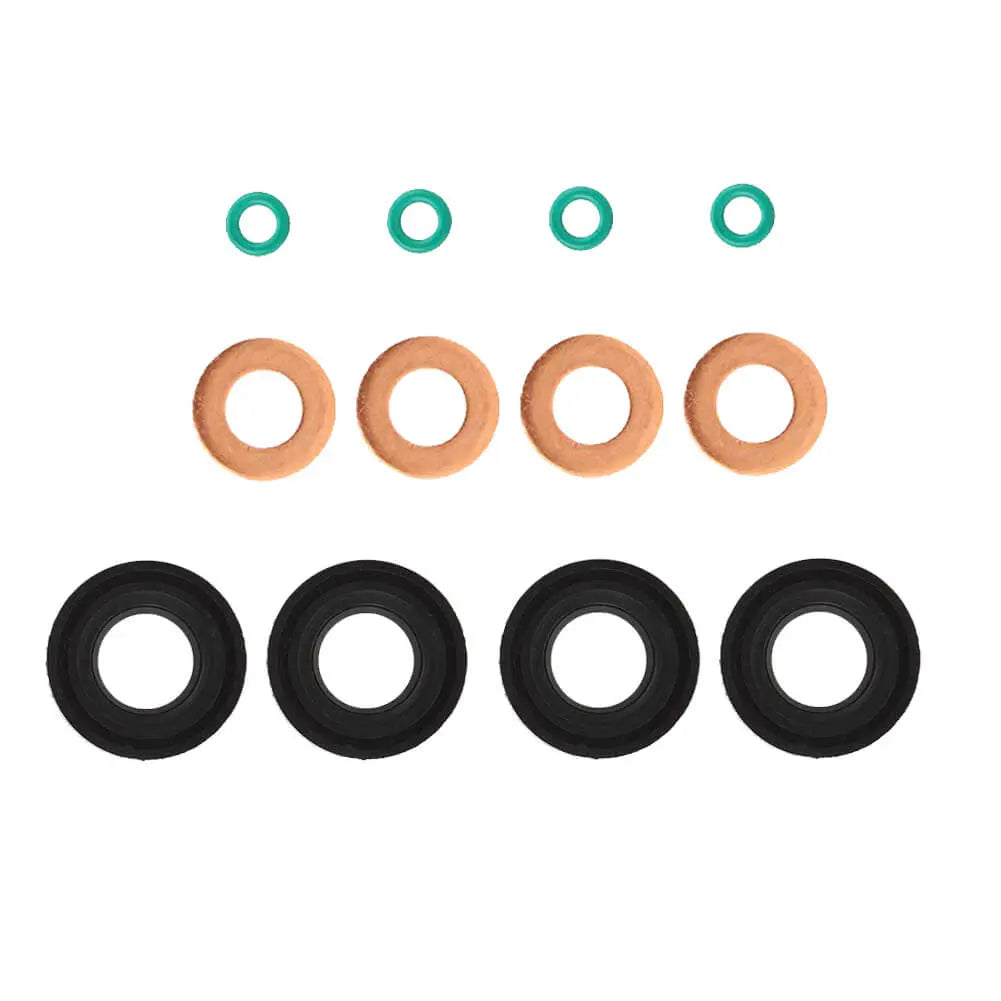

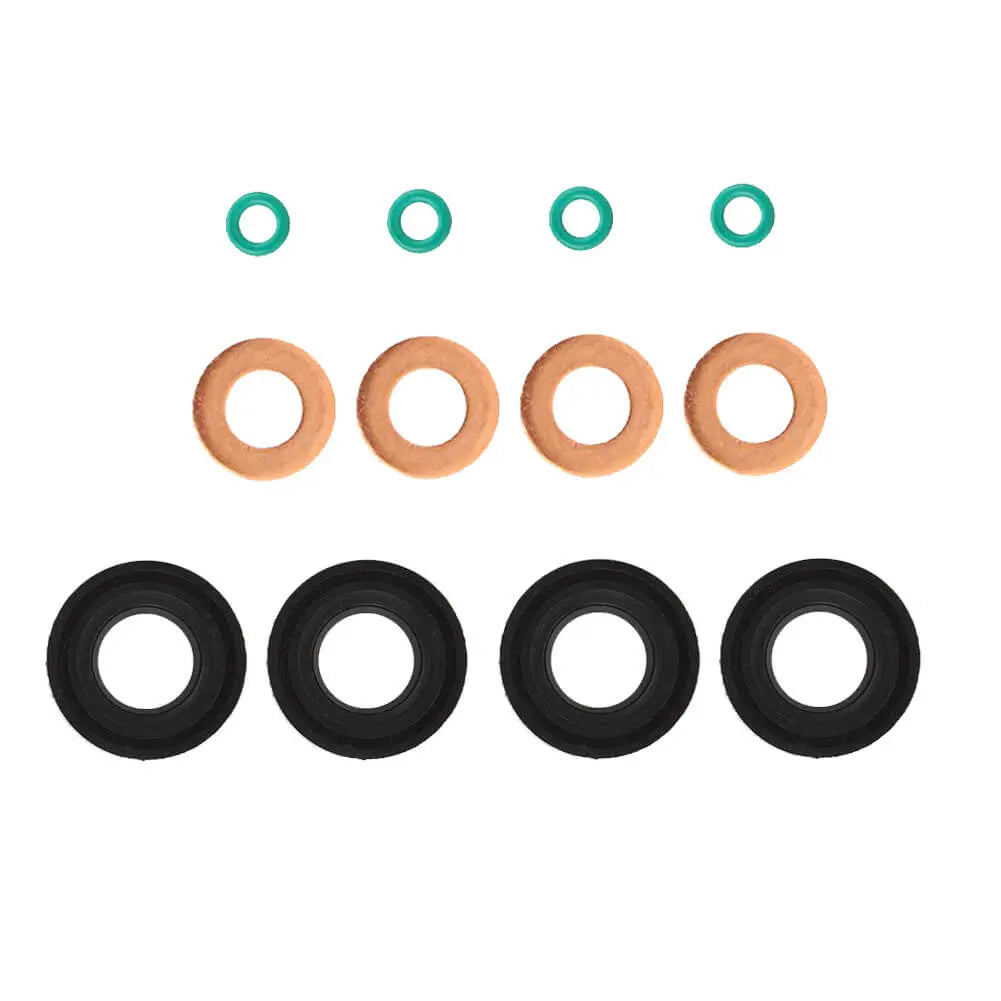

6 Pcs Fuel Injector Nozzle Copper For Fiat Ducato Scudo Ulysse - 9401981969, 55192494, 55215424, 55204259

In stock, 29 units

Sale price£7.49

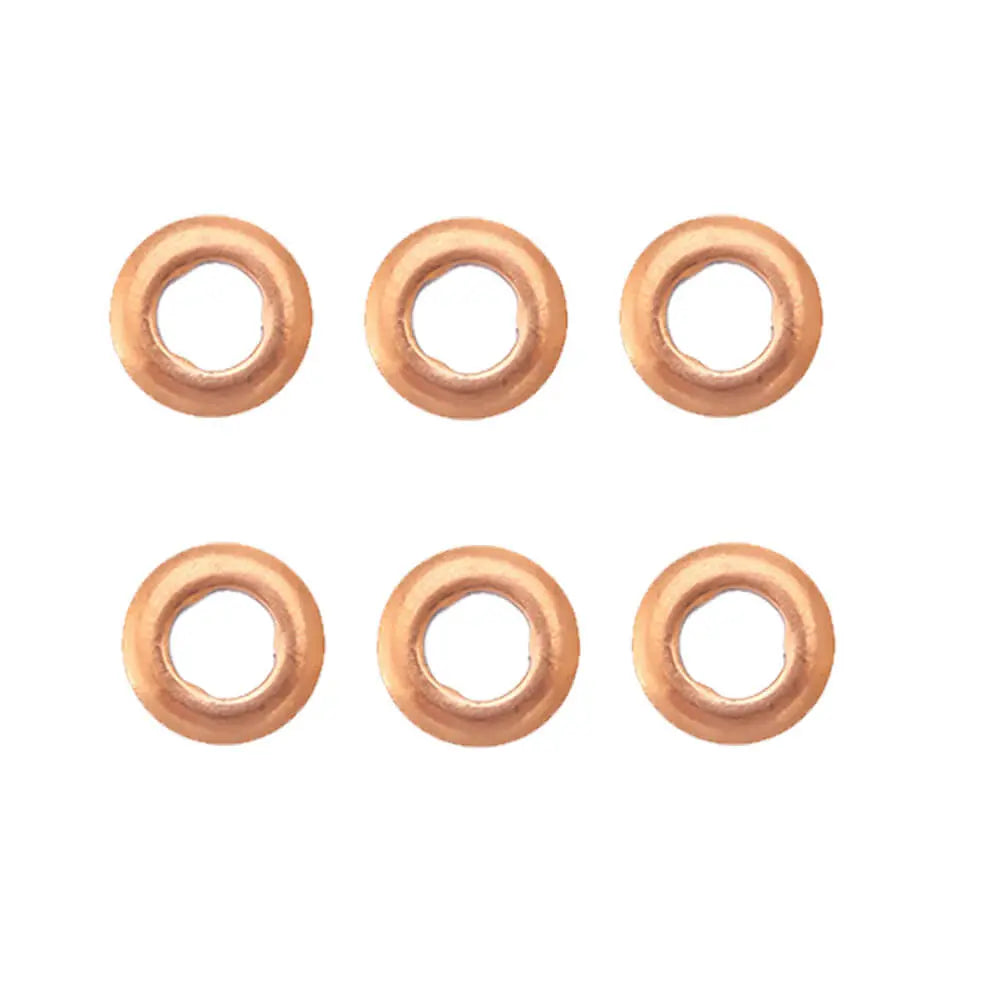

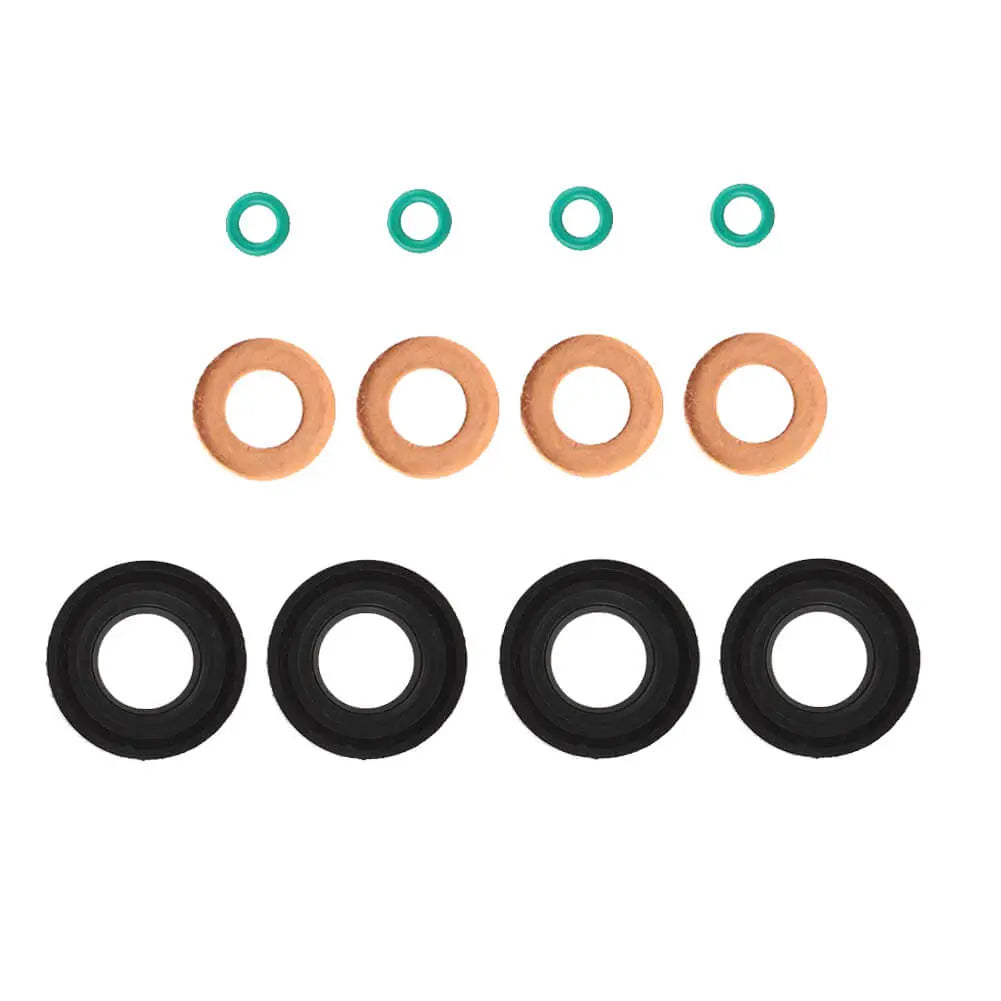

Fuel Injector Seal Washer O-Ring Set For Peugeot Expert Partner - 1982.G6, 1981.95

In stock, 50 units

Sale price£14.99

Fuel Injector Seal Washer O-Ring Set For Peugeot 2008 206+ 207 208 3008 308 4008 5008 508 - 1982G6, 198194

In stock, 50 units

Sale price£14.99

Fuel Injector Seal Washer O-Ring Set For Ford B-Max C-Max Fiesta Focus Galaxy Grand C-Max Mondeo Tourneo Transit - 1691340

In stock, 50 units

Sale price£14.99

Fuel Injector Seal Washer O-Ring Set For DS DS3 DS4 - 1982G6, 198195, 198194

In stock, 50 units

Sale price£14.99

Fuel Injector Seal Washer O-Ring Set For Citroen Berlingo C3 C4 C5 Dispatch DS3 DS4 DS5 Spacetourer - 1982G5, 198194

In stock, 50 units

Sale price£14.99

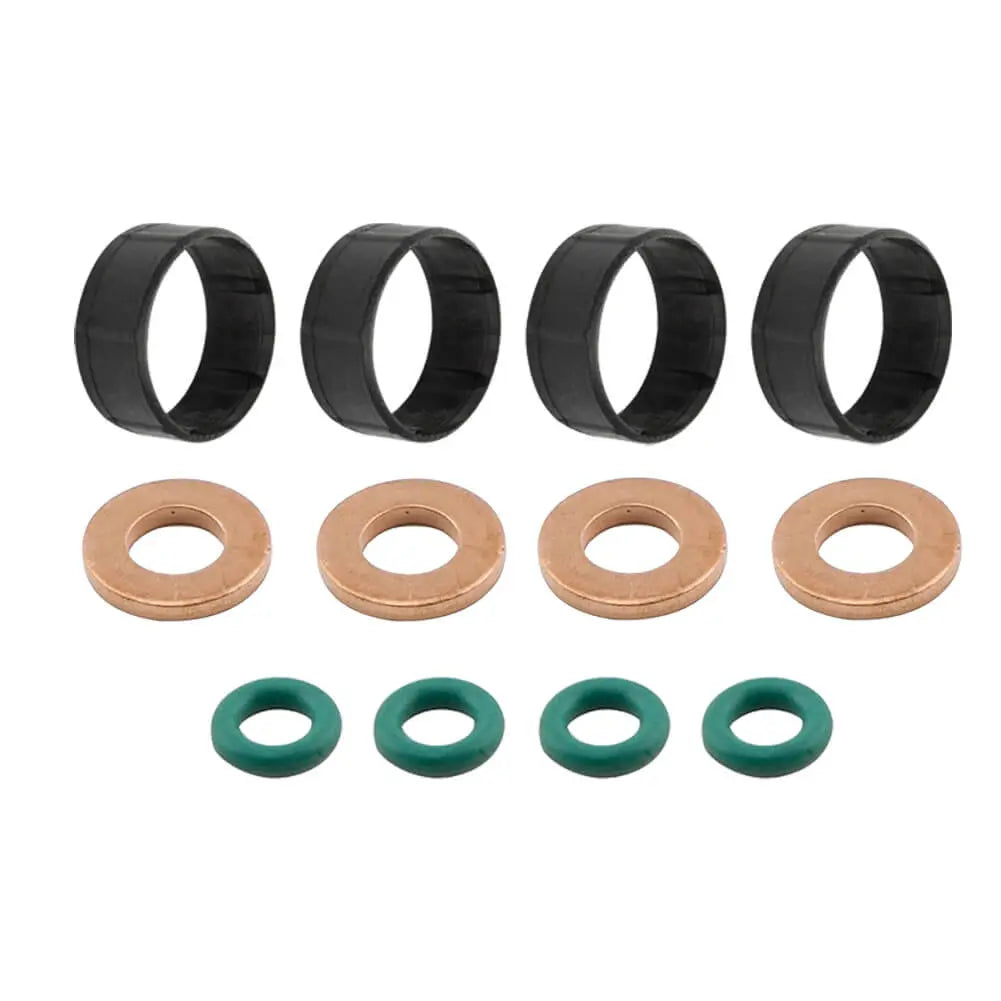

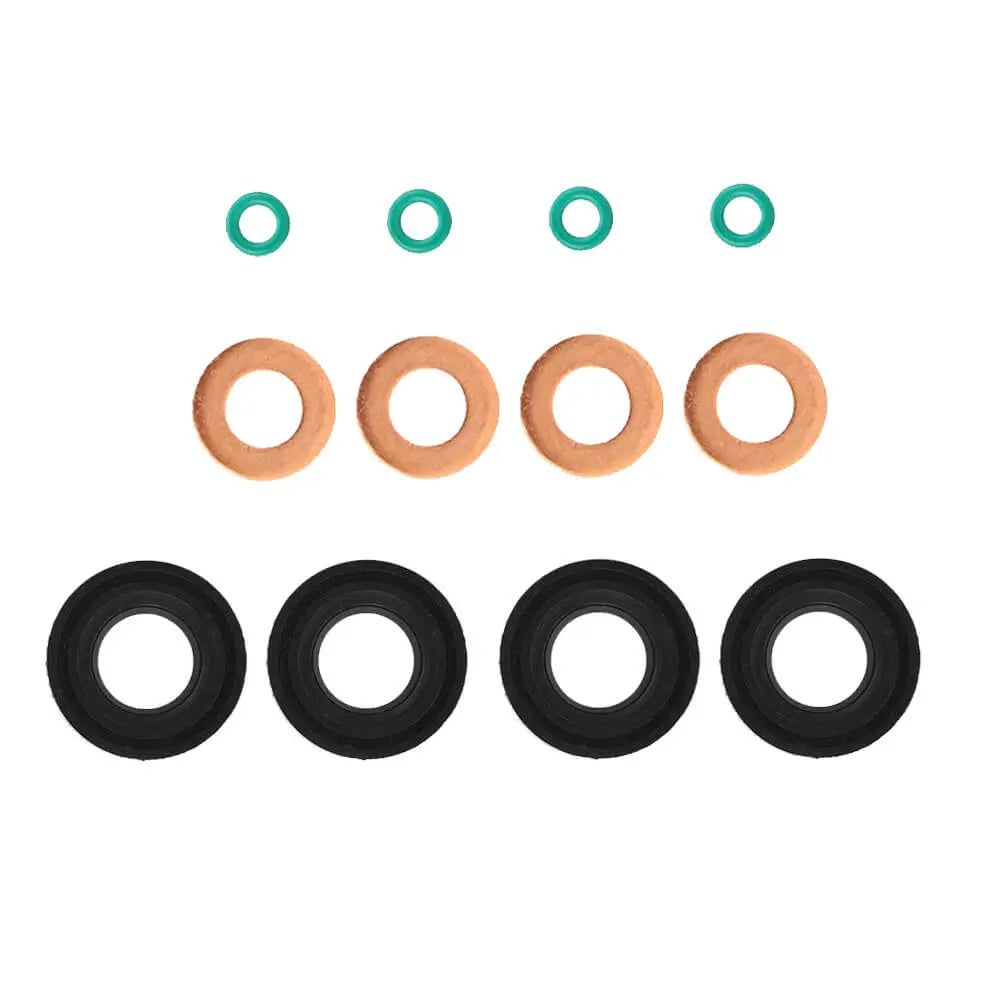

Fuel Injector Seal Washer O-Ring Kit Set For Ford Fiesta - 1348625, 1204698, 114806

In stock, 50 units

Sale price£8.99

Fuel Injector Seal Washer O-Ring Kit Set For Peugeot 107 206 207 307 1007 Bipper - 198184, 2S6Q9E568AA

In stock, 50 units

Sale price£8.99

Fuel Injector Seal Washer O-ring Kit Set For Citroen Nemo Xsara Enterprise C1 C2 C3 - 0348T8, 1982F7, 198184

In stock, 50 units

Sale price£8.99

Fuel Injector Seal Washer O-ring Kit For Citroen Berlingo Xsara C2 C3 C4 C5 Dispatch - 198185, 198263, 198283

In stock, 50 units

Sale price£12.90

Fuel Injector Seal Washer O-ring Kit For Ford C-Max Fiesta Focus - 1233684, 1233685, 1314368

In stock, 50 units

Sale price£12.90

Fuel Injector Seal Washer O-Ring Kit For Peugeot 1007 206 CC 206 207 3008 307 308 407 5008 Expert Partner - 198185, 198263

In stock, 49 units

Sale price£12.90

Injector Seal Washer O-Ring Kit For Citroen Berlingo Xsara C5 C4 Dispatch (2004 - Onwards) 1609848080, 189173

In stock, 50 units

Sale price£14.99

Fuel Injector Seal Washer O-Ring Set For Skoda Octavia Roomster Fabia Superb Yeti Rapid - BK2Q6K780BA, 1760803

In stock, 50 units

Sale price£11.49

Fuel Injector Seal Washer O-Ring Set For Peugeot Boxer (2011 - Onwards) 1233685, 198283

In stock, 50 units

Sale price£11.49

Fuel Injector Seal Washer O-Ring Set For Land Rover Defender (L316) (2011 - 2016) LR037698,1233683, 1233684, 1233685

In stock, 49 units

Sale price£11.49

Fuel Injector Seal Washer O-Ring Set For Ford Transit Mk7 V362 V363 Ranger Mk4 Tourneo (2007 - Onwards) 1233683, 1233684, 1233685

In stock, 50 units

Sale price£11.49

Fuel Injector Seal Washer O-Ring Set For Citroen Relay (2011 - Onwards) 03L103070A, 1760803

In stock, 50 units

Sale price£11.49

Fuel Injector Seal Washer O-Ring Set For Audi A3 A1 (2009 - 2015) 03L103070A, 03L103070A, 1760803

In stock, 50 units

Sale price£11.49

Injector Seal Washer O-ring Kit For Fiat Scudo For Volvo S40 V50 C30 (2005 - Onwards) 30757304, 189173, 198299

In stock, 50 units

Sale price£14.99

Injector Seal Washer O-ring Kit For Peugeot Partner 206 207 307 308 407 3008 (2004 - Onwards) 1609848080 1609848280

In stock, 50 units

Sale price£14.99

Injector Seal Washer O-ring Kit For Ford Fiesta Fusion Focus Galaxy Mondeo C-Max Fiesta Grand C-Max B-Max - 1233683, 3M5Q-9R524-AA

In stock, 50 units

Sale price£14.99

Filters (0)